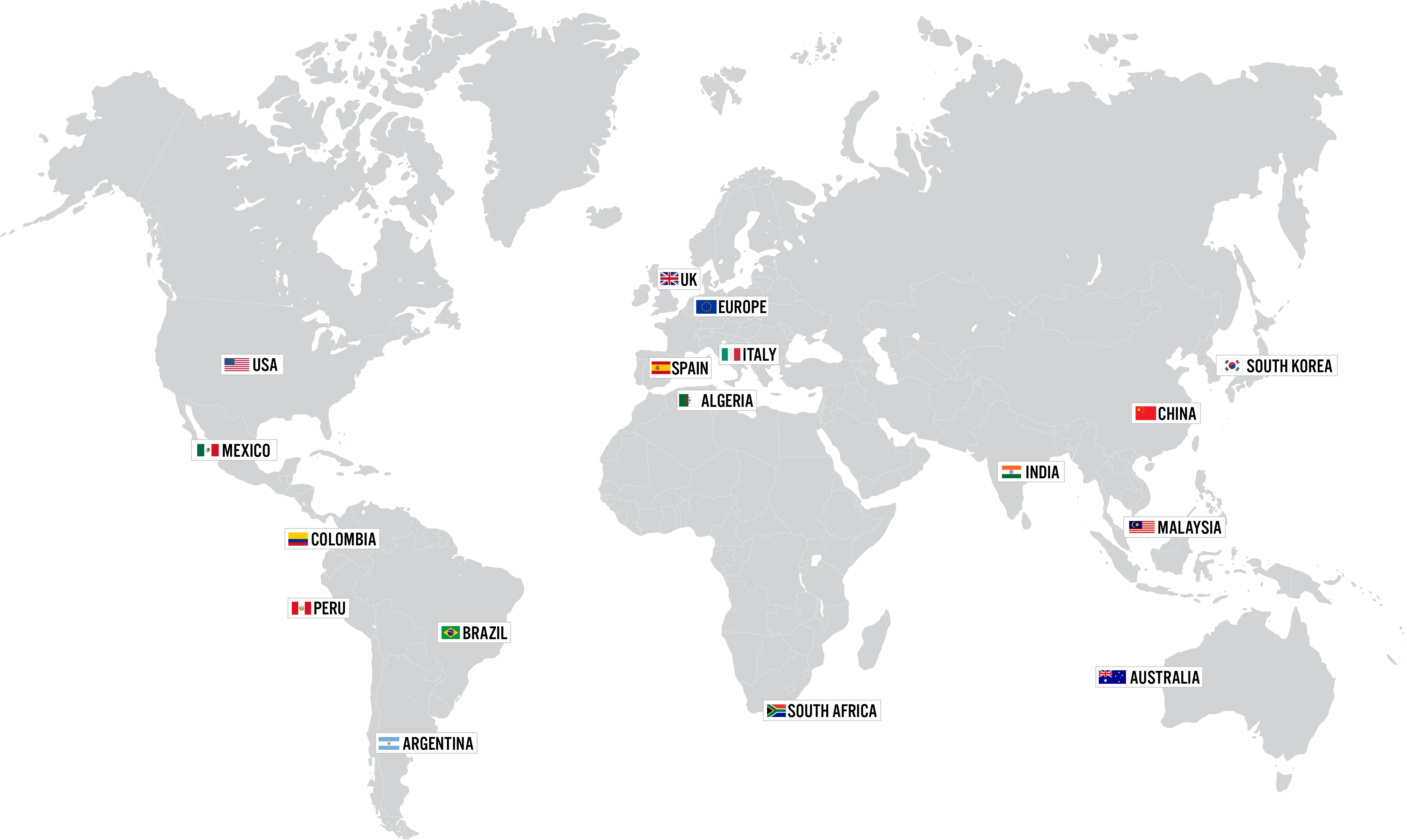

DOVE SIAMO

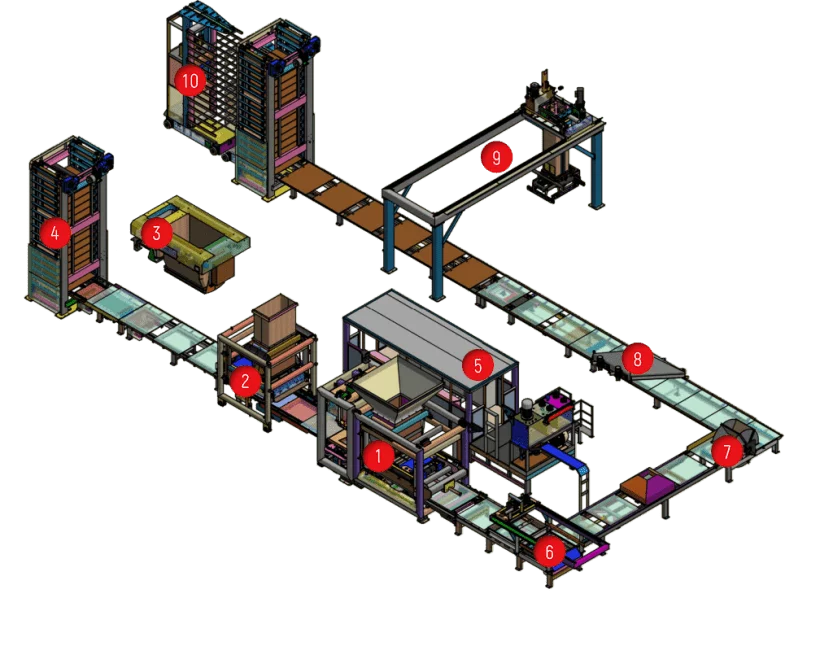

Block Machine complete line

Click on the machine of interest to discover more information about it, remember that you can always ask for help from our customer service.

2. Multilayer

This multilayer option allows the possibility to expand the production range by obtaining stratified products. This, among other things, allows you to have multiple colors pavers.

1. Block Machine

In the picture, the best selling vibropress, BX 1200.

The core of the system, fully integrated with the rest of the line.

Ask more informations to our customer service to have full support and informations!

3. GRK - Aerial Bucket

Space and energy saving this aerial hopper or "Travelling Bucket" it's the smartest way to transport concrete from the dosage line to the press unit.

4. Elevator

This automated pallet Elevator, in couple with the Fingercar and the Lowerator will take care of the whole stocking and curing procedure.

5. Control Room

"Brain" of the entire line our control room has been designed considering not only the technological integration and the possibility of centralizing the feedback from every part of the plant, but also the well-being of the operators, guaranteeing a clean and quiet place in which to work.

6. Pallet table recovery system

This smart "Magnetic Robot", in couple with the pallet storage will stock and feed the cleaned tables to the vibropress at the desired rate.

7. Turntable system

This simple but yet very effective operation will extend the life of your tables, optimizing the whole procedure.

8. Table cleaning procedure

Those brushes are the most important part in having a clean system, thanks to our experience the speed and the brushes are custom made to obtain best result in cleaning the tables, no matter the vibroformed materials.

9. ST - Heavy duty stacker

Always keeping safety first as a priority, this machine, being subject to severe wear, has evolved over the years to ensure the least possible maintenance using components of the highest quality.

10. TR - Automatic transborder

Fully automatic, this heavy load transborder will take care of stocking fresh products in the curing rooms, unstocking dried ones and providing a continuous intake to the pallettization line.